MTA EMTC

GEAR TECHNOLOGY SOLUTIONS FOR

ELECTRIC 2 WHL, 3 WHL & 4 WHL

MTA EMTC

GEAR TECHNOLOGY SOLUTIONS FOR

ELECTRIC 2 WHL, 3 WHL & 4 WHL

Low Speed

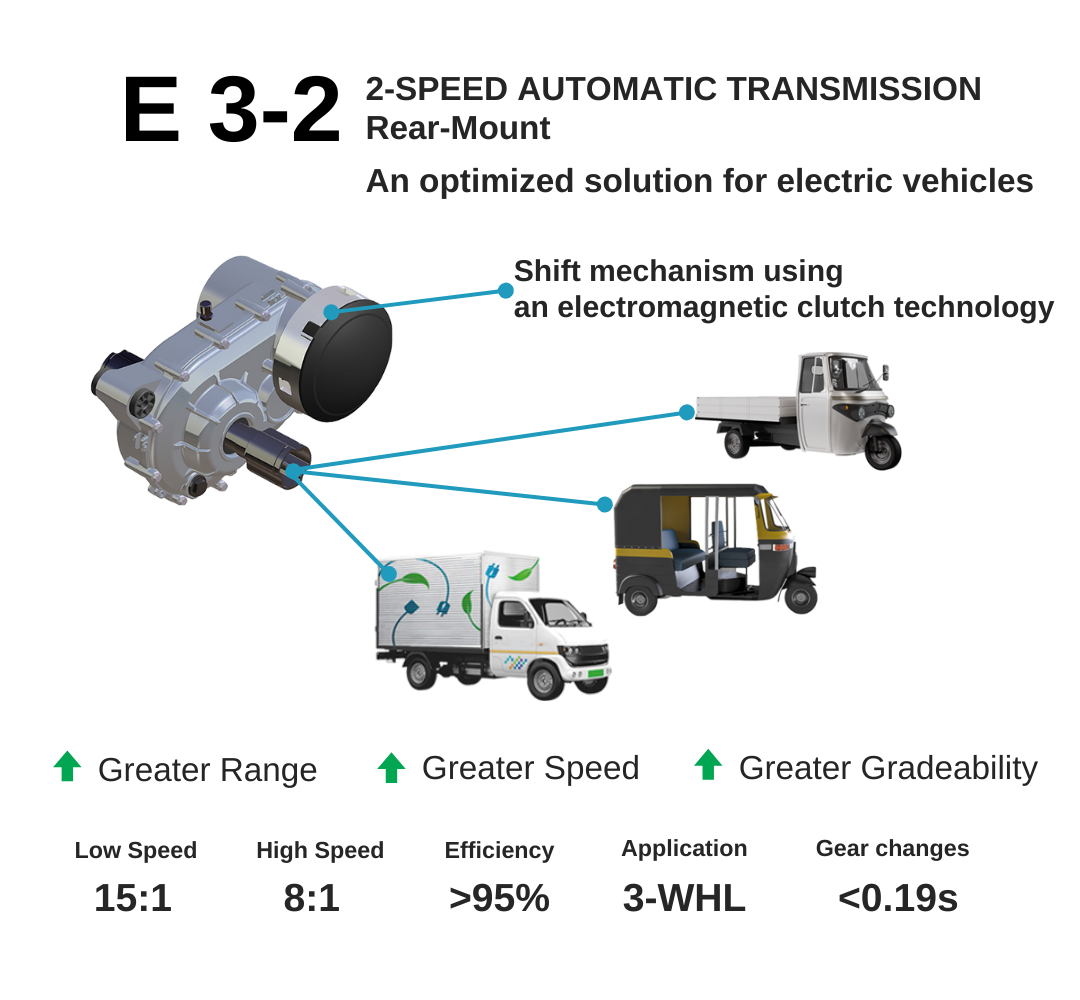

E3-2

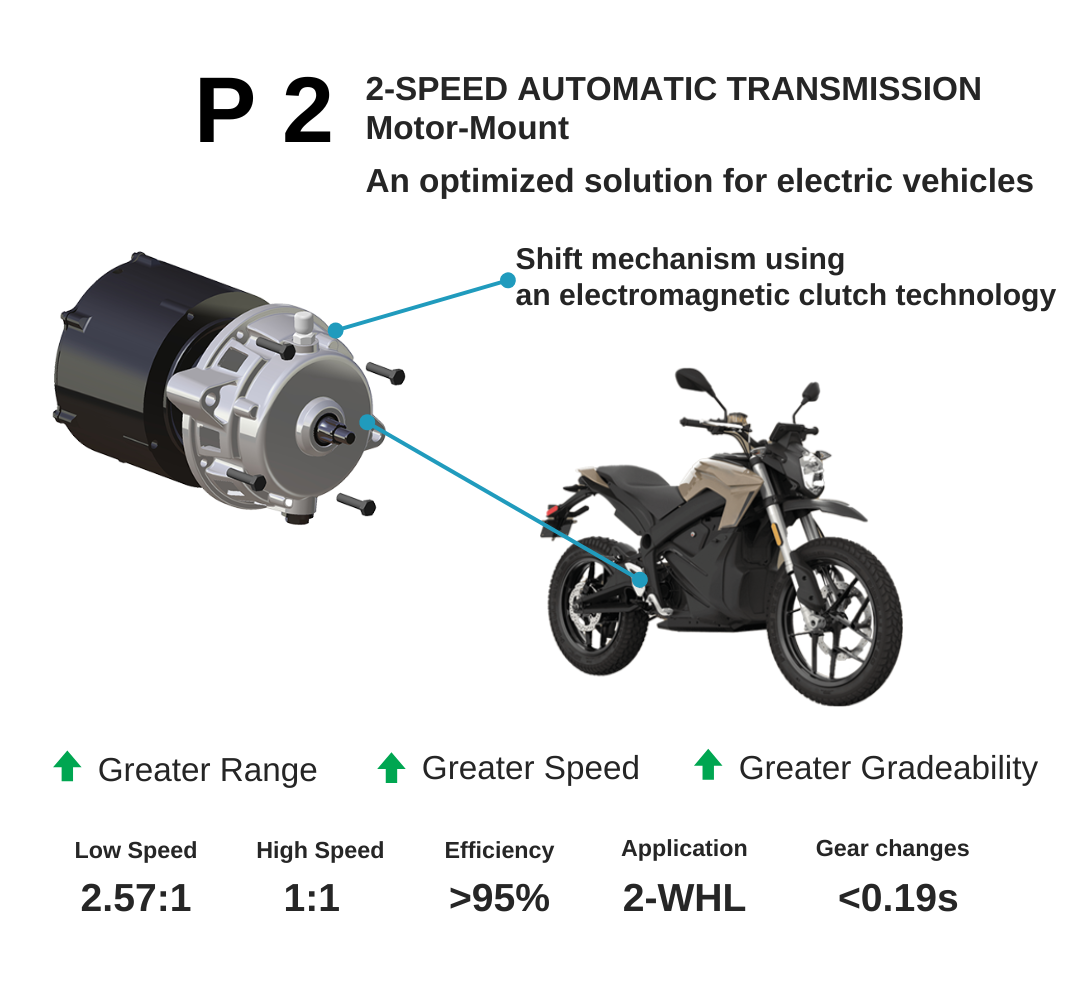

P2

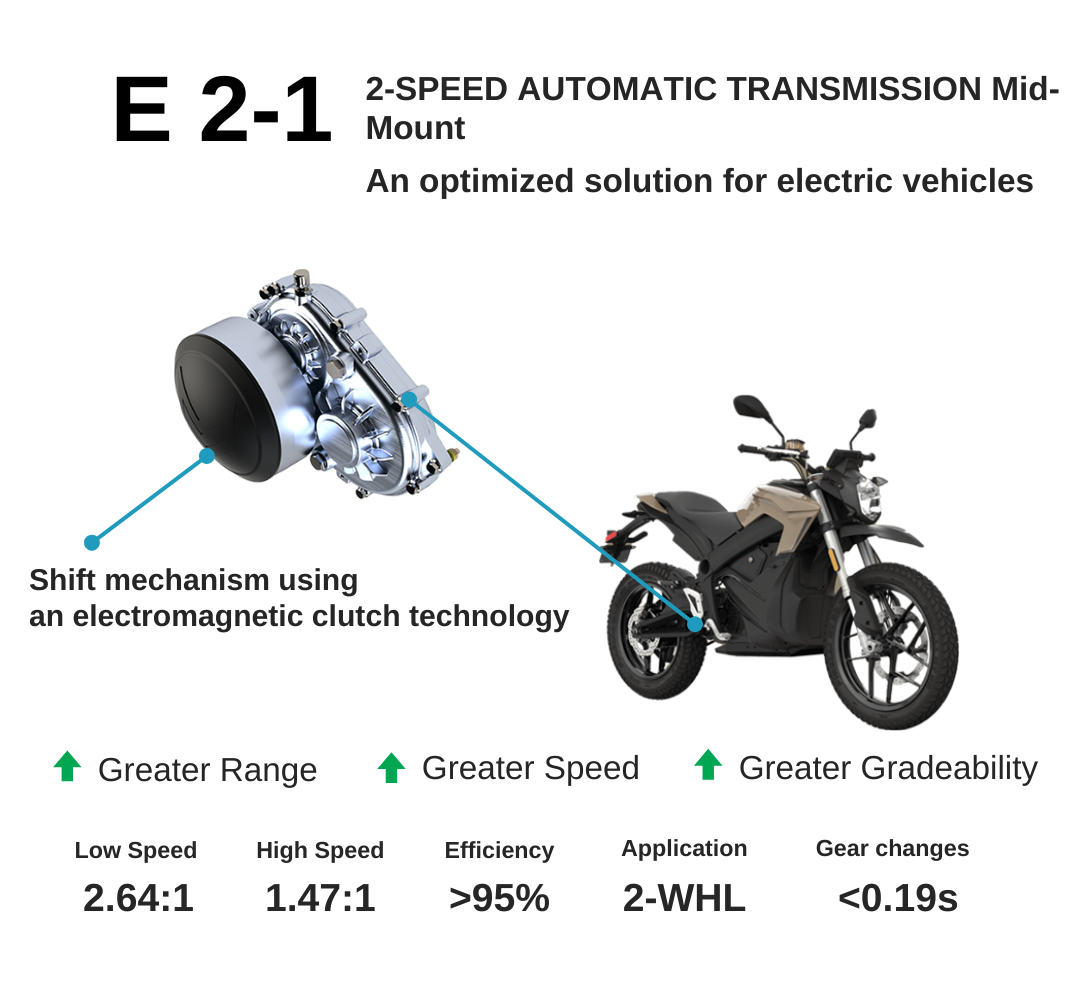

E2-1

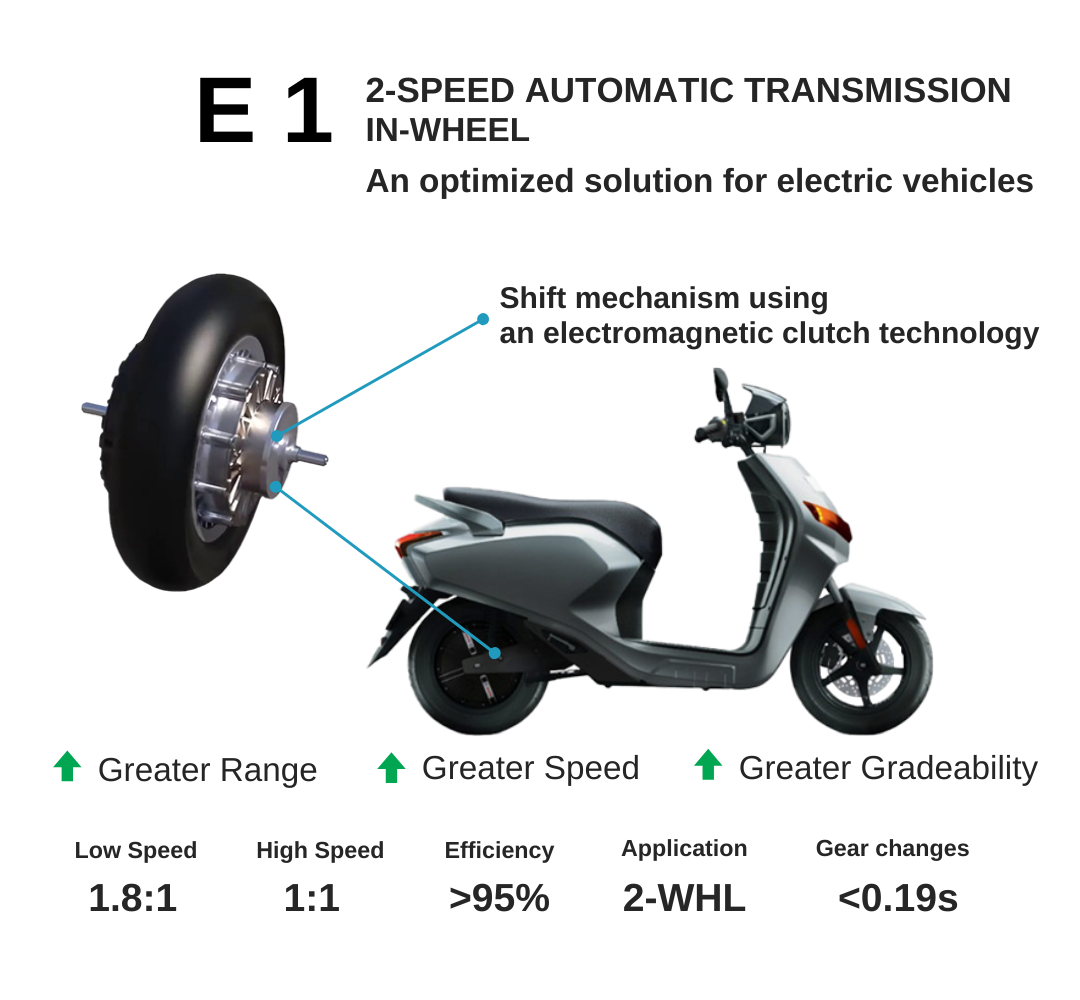

An optimized solution for electric vehicles

2-SPEED AUTOMATIC TRANSMISSION

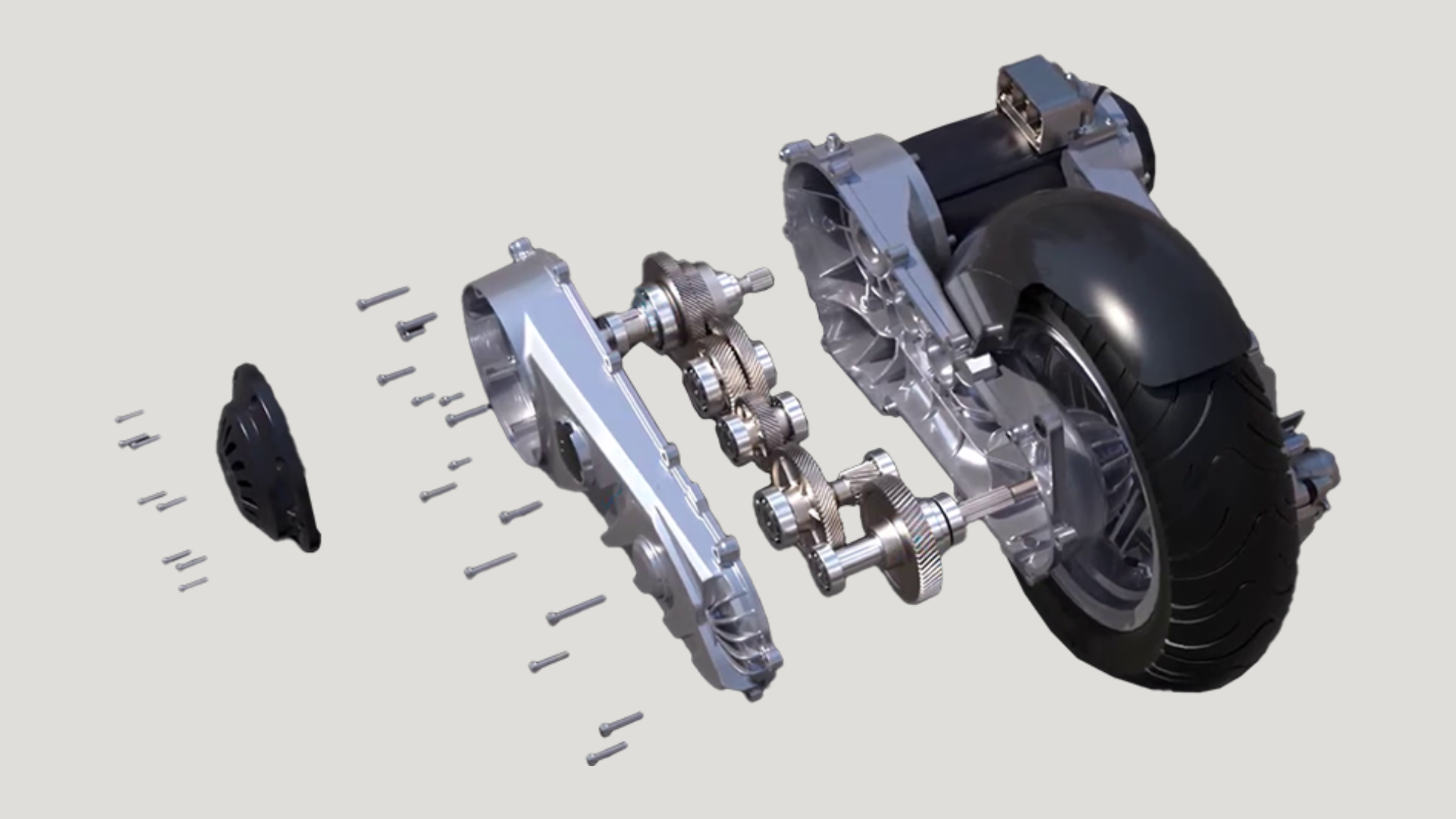

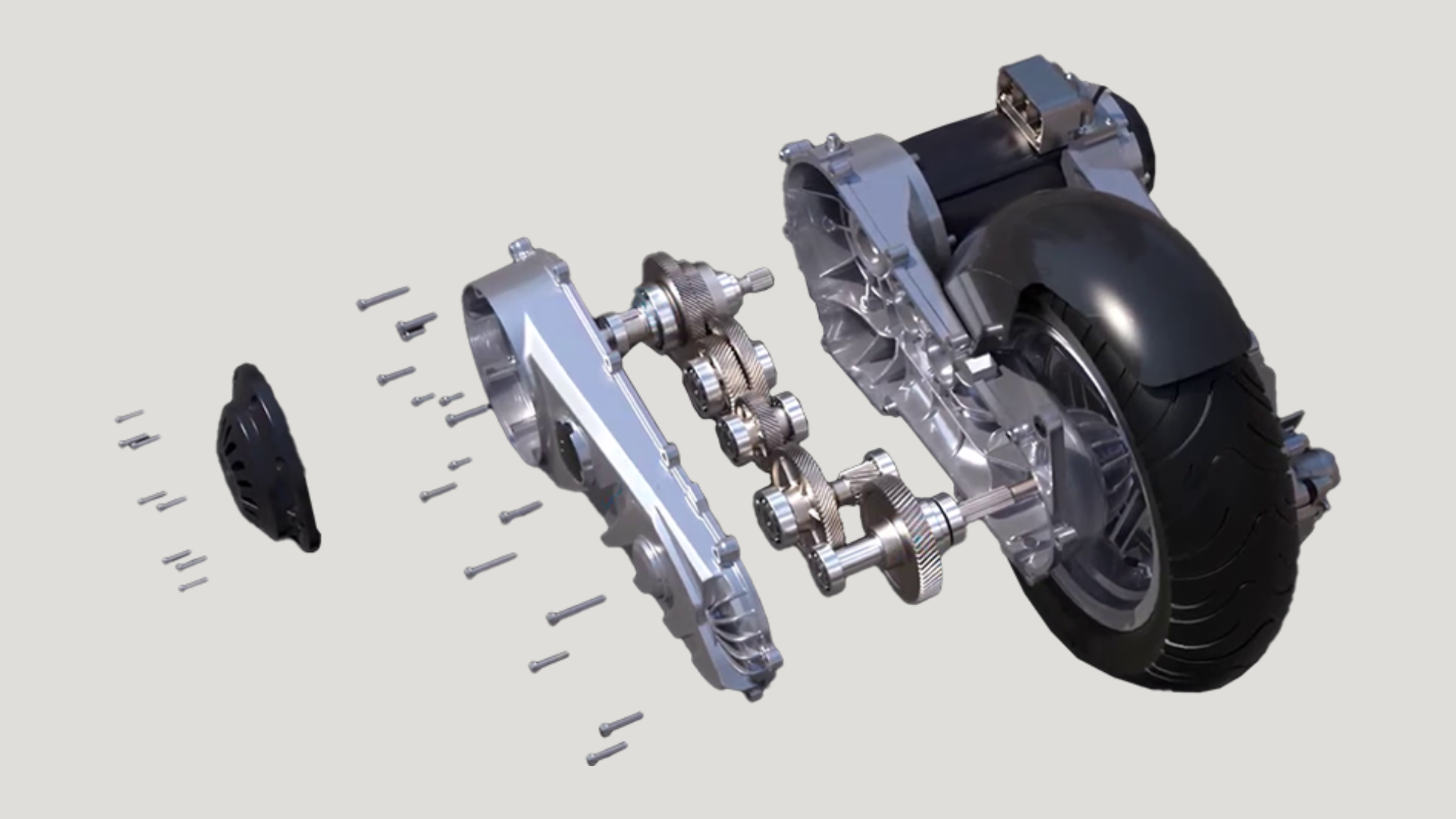

IN-WHEEL

2-SPEED AUTOMATIC TRANSMISSION

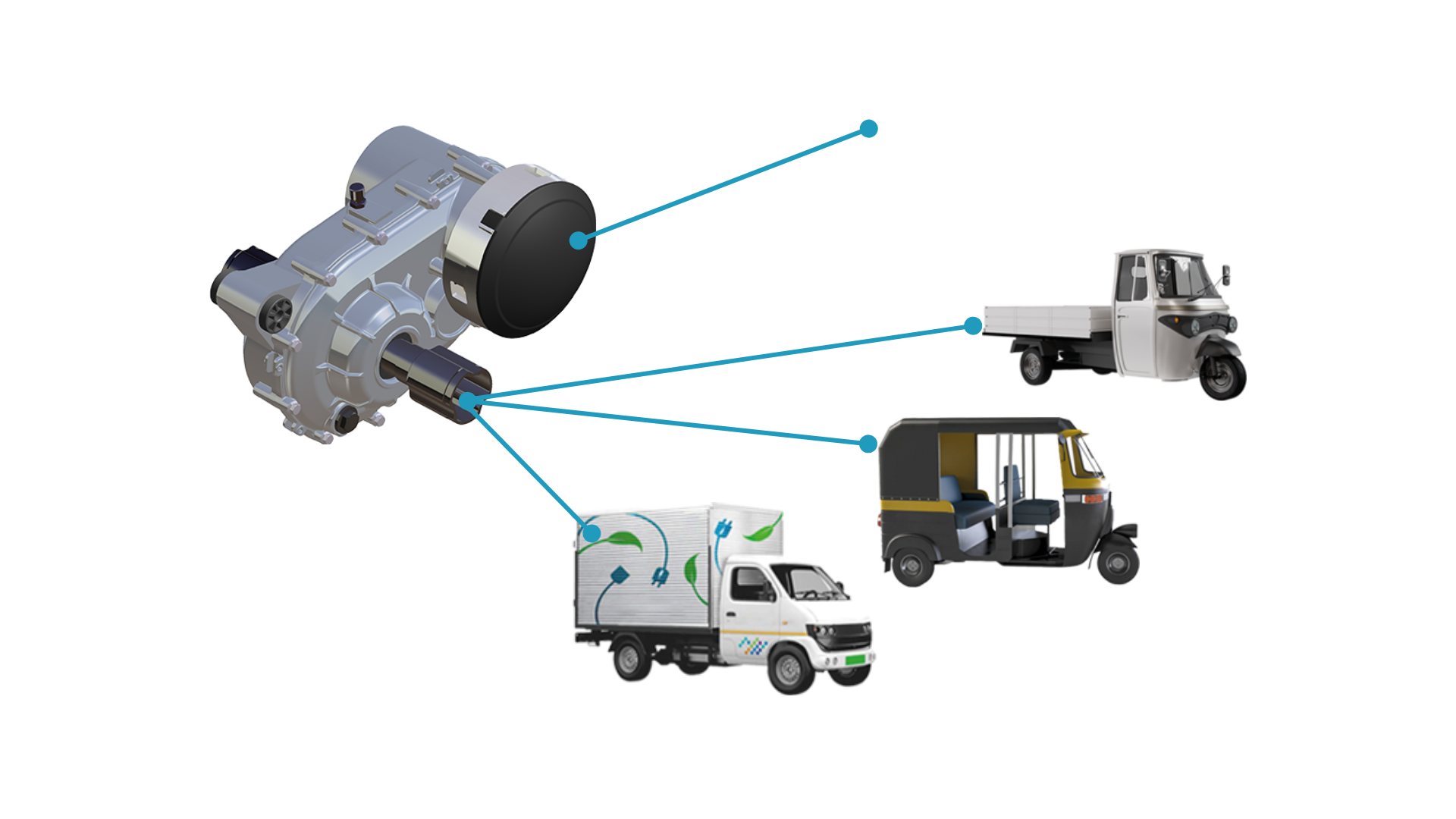

Rear-Mount

2-SPEED AUTOMATIC TRANSMISSION

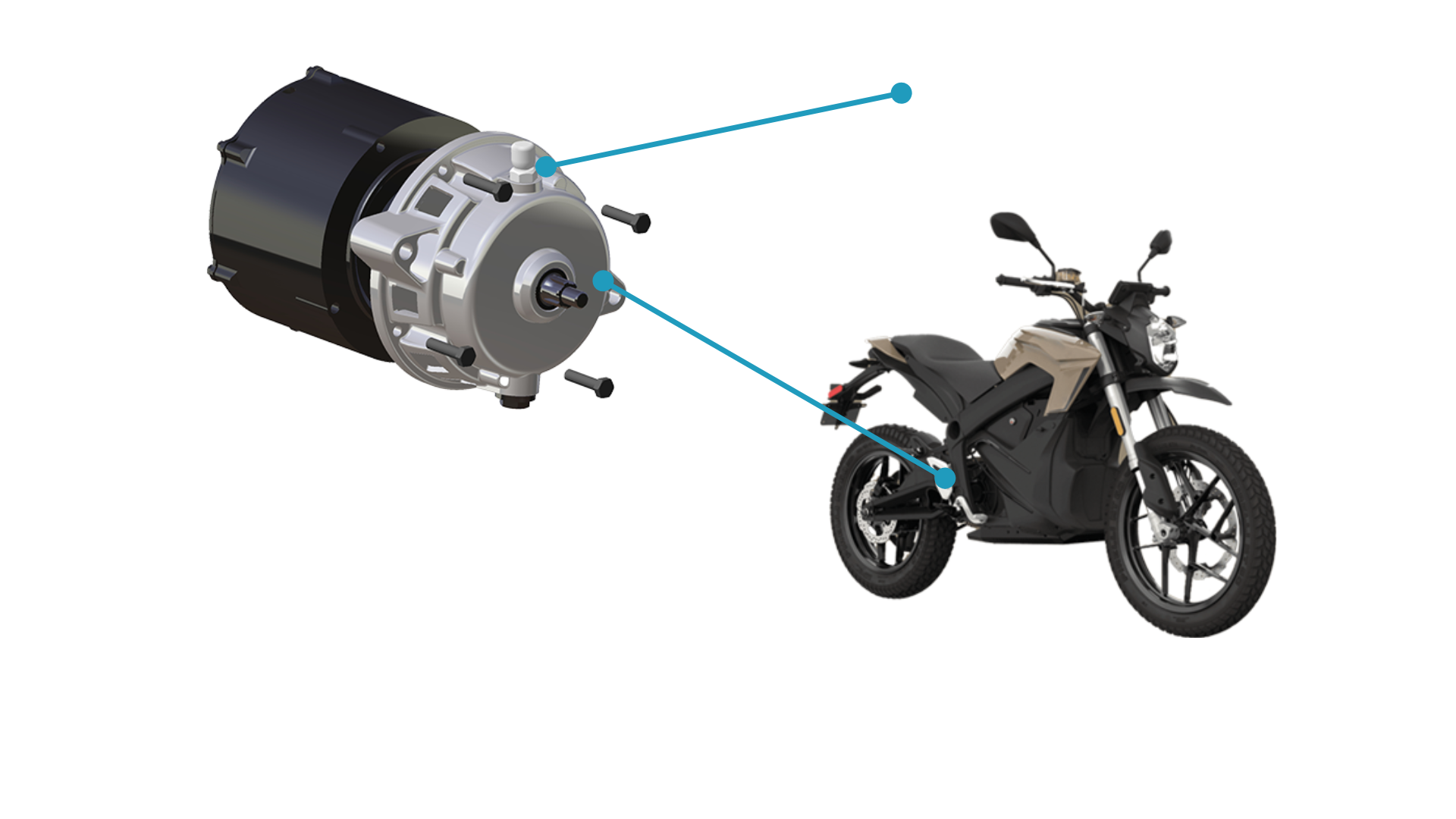

Motor-Mount

2-SPEED AUTOMATIC TRANSMISSION

Mid-Mount

Shift mechanism using

an electromagnetic clutch technology

Shift mechanism using

an electromagnetic clutch technology

Shift mechanism using

an electromagnetic clutch technology

Shift mechanism using

an electromagnetic clutch technology

![]() Greater Range

Greater Range

![]() Greater Speed

Greater Speed

![]() Greater Gradeability

Greater Gradeability

High Speed

Efficiency

Application

Gear changes

1.8:1

2.64:1

2.57:1

15:1

2-WHL

3-WHL

<0.19s

>95%

1:1

1.47:1

1:1

8:1

E1